{results_count} results for {phrase}

Display {results_count} results for {results_count_total}

No account yet register easily via the button below. Need help? Then feel free to contact with us.

€ 6,05 - € 1.906,51Price range: € 6.05 through € 1,906.51 (incl. VAT)

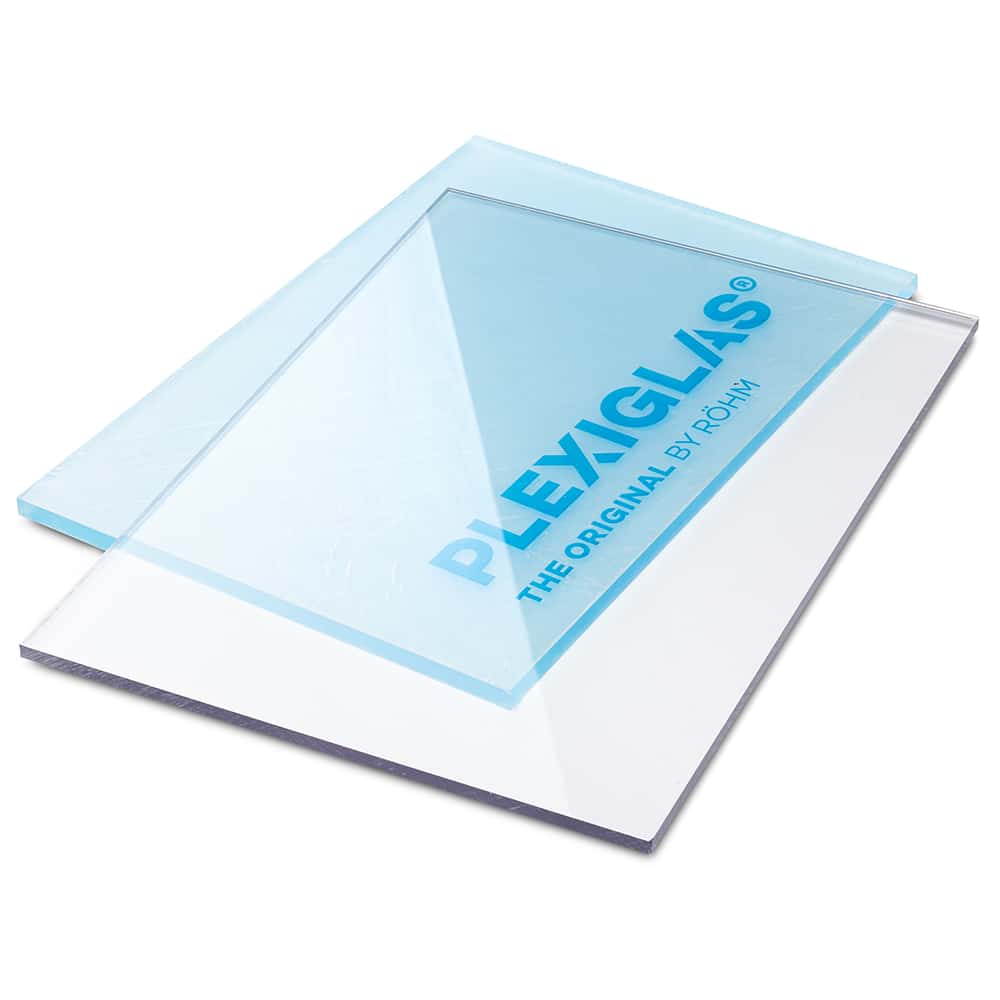

Extruded clear acrylic (XT plexiglass) from Pyrasied is a high-quality material with exceptional clarity. Pyrasied stocks a wide range of acrylic sheets in both cast (GS) and extruded (XT) quality, available in clear and colour. Both types are of excellent quality, but differ in production method.

Extruded acrylate (XT acrylate) is produced via a continuous extrusion process. In this process, the liquid acrylic (PMMA) flows out of the reactor and is brought to the desired thickness via rolling. This process produces a dimensionally stable and cost-efficient plastic sheet.

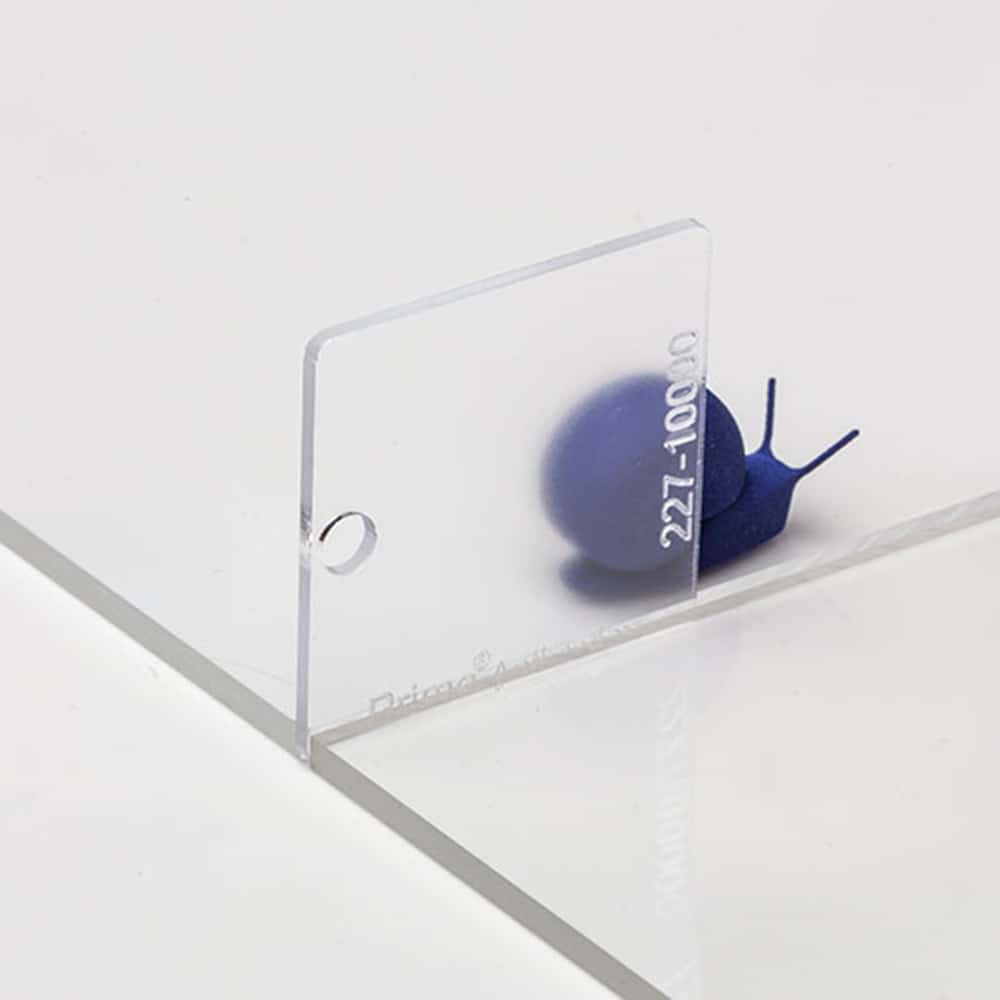

The biggest advantage of XT acrylic is that it has hardly any thickness tolerance. The sheets therefore always have exactly the thickness you order. This makes extruded acrylic particularly suitable for applications where the material must fit into a profile or a perfectly flat surface is required.

Clear XT plexiglass is one of the most popular transparent plastics thanks to its exceptional clarity. With a light transmission of 92%, it is even brighter than glass. In addition, acrylic is 25 times stronger than glass, lightweight and easy to work with.

Pyrasied offers extruded clear acrylic (XT) in thicknesses from 2 to 20 mm. Ecocrylic XT is also available, which is a 100% recycled variant. These sheets are available directly from stock.

Looking for thicker acrylic? Then choose clear acrylic block (up to 100 mm thick, cast quality).

For thinner precision applications, you can opt for Hesaglas, a high-quality cast acrylic variant.

Clear extruded plexiglass is widely used in such applications as:

XT acrylic is easily processed using techniques such as sawing, milling, lasering, hot bending, gluing, drilling, faceting, polishing, matting and printing.

Want to know more about the possibilities? View all operations on pyrasied.com.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Colour tint | P20010 PMMA XT clear, P20710 Ecocrylic XT clear, P22710 PMMA XT clear one-sided anti-reflex, P27110 PMMA XT clear optical |

| Surface structure | one-sided satin, glossy |

| Thickness | 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm |

| Dimensions | Customised, 3050x2050mm, 3050x1250mm, 3000x1000mm, 2000x1500mm, 1500x1250mm, 1500x1000mm, 1500x625mm, 1000x1000mm, 1000x500mm, 500x300mm, 300x250mm |

| Colour | clear |

| Article group | 413 - Bright XT |

| Commodity code | 39205100 |

| Recycled plastic | No |